Micro mold parts can be found in micro electronics, cell phones, telecommunications, surgical tools, hearing aids, medical devices, antennas, connectors and more. We were interested in learning more about those components and the technology behind and talked to Aaron Johnson, Vice President of Marketing & Customer Strategy at Accumold. Accumold has been exhibiting with us at the 10th anniversary of our WT | Wearable Technologies Conference 2016 EUROPE in Munich this February and will also join us a the 5th anniversary of the WT | Wearable Technologies conference 2016 USA in San Francisco on July 12-13. Feel free to drop by at their booth to talk to them directly.

What is micro-molding? Can you give us a short introduction?

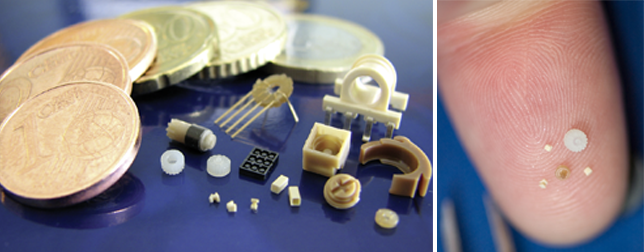

In simple terms micro-molding is the art of producing small and micro-sized injection molded plastic parts and components. That being said, size is only one factor when defining what we believe is true micro-molding. At Accumold we define micro-molding in one of three ways; either micro in size, micro in features, or micro in tolerances – in many cases it’s all three. True micro-molding pushes the limits of injection molding. It’s not uncommon for there to be tolerances well under 25 µ (in some cases just two or three), or geometries where there are thin-wall sections that are only a hundred microns in thickness. In fact our smallest commercial part to-date is only 800 µ at its largest feature.

What are the biggest challenges you have to face during the production process?

Because we’re dealing with such small and tiny parts handling oftentimes can be a challenge. Environmental factors like static can sometimes cause parts to float away. So you must have a very controlled environment in order to handle some of these micro parts. You also have to have some in ingenuity when designing automation systems for inspecting or handling them for packaging. It’s also very helpful to coordinate with your customer on how their incoming inspection will qualify and verify product. Correlation between measurements when you’re only dealing with a few microns becomes very critical.

Which is the best material to process? And why?

We have several materials that we like to process. It really depends upon customer’s need and the situation at hand. Material choice and future performance have a direct relationship. We have spent the last 30 years gaining experience on what materials work best in particular situations. We know for instance that a material like LCP will fill fine features and high aspect ratio geometries where material like PEEK maybe challenging to fill extremely fine features. Some of our favorite materials to process besides LCP are high flow polycarbonate, ABS and perhaps even some of glass-filled nylon’s. That being said we do successfully process a lot of PEEK, PPA, PI, PBT and Ultem® (PEI) materials for many of our customers.

What was the most challenging job so far?

That’s a really tough question to answer since most of the projects we take on are pushing limits of micro injection molding. We often tease our engineering team because they ask for simple projects and that’s just not what we do – everything we do is challenging. Some of the more challenging things we’ve taken on over the years are projects that include micro lenses for sensors or imaging optics where they have extremely tight positional tolerances (± 2 µ), material clarity and surface finish requirements that are often times on the extreme end as well.

Is there any advice you can give our clients if they need molded parts for their products?

There are three main things that we recommend for anyone designing plastic components for micro-molding. First, start with your ideal design. There will be challenges along the way and not everything that can be drawn can be made, but start with what you think you’ll need and work from there. Second, talk to your micro-molder at the concept stage. Start the DFM (design for manufacturability) process early so that you know where you can and cannot push the limits of your design. And third, always remember that the basic rules of injection molding do still apply. Even though the parts are tiny they still need a gate and ejection location, they often still require draft, and you still have to be able to open and close the mold.

What are the advantages / disadvantages of 3D printing compared to micro-molding?

At this moment in time the rapid prototyping process can’t meet the quality requirements for many of the parts that we produce in terms of positional tolerances, features sizes, and material surface. We’re excited to see where advancements in 3D printing are going because we believe it will be a great enhancement to the creative design process. At the moment, because we build hard-steel tools for our prototypes, one big advantage is knowing that your design is a production capable process and your prototypes will function at production-like levels. To-date, the rapid processes are not quite there. That being said, one big disadvantage of hard-steel prototyping is the speed and cost. Mold building requires a much larger investment in time and resources that one might find with a few 3D printed parts.

What is your favorite wearable device?

I am a techno geek. I love my gadgets. Whether it’s my fitness tracker or my smartwatch I am a big fan. But I think my favorite wearable device is one that we probably don’t think of as “wearable” … my smartphone. If you think about it, it’s on my person pretty much 24/7. I might not have it around my wrist or my lapel but it is nonetheless something that I am “wearing” all the time. If I were to pick an app it would be myfitnesspal. It works seamlessly with both with my watch and my phone and as of this writing I am on an 826 day streak of logging my diet. Which reminds me, it’s time for a snack. 🙂