First things first, what is it graphene and why is it called the new super material?

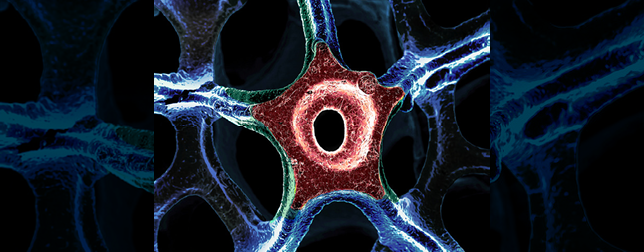

Graphene is in simple terms, a thin layer of pure carbon; it is a single, tightly packed layer of carbon atoms that are bonded together in a hexagonal honeycomb lattice. It is the thinnest compound known to man at one atom thick, the lightest material and the strongest compound discovered, the best conductor of heat at room temperature and also the best conductor of electricity known. Other notable properties of graphene are its unique levels of light absorption. All these properties make graphene an excellent material to make advancements within different scientific disciplines particularly in electronics and biotechnology.

Of course, wearables couldn’t be less and also come companies started exploring the capabilities of graphene applied for wearables. Bonbouton is a company who was a winner of the WT | Wearable Technologies Innovation World Cup 2016/2017 for Smart Clothing. They developed a smart clothes platform that lets the user measure and track vitals as well as activity in a comfortable and unobtrusive manner. This is possible thank you to a graphene thermal sensor suitable for clothes. The electronics are fitted into a button, one of the oldest technologies next to the wheel. This allows the user to swap different smart clothes from your wardrobe and allows standardization for brand partners to make clothes that match your personal taste & style. You can read more information about Bonbouton (Flextrapower) here.

Another recent discovery was during the MWC in Barcelona this week, in Hall 8 and almost hidden from the busy booths and packed halls were the hidden gem of the graphene pavilion. In a small space and with not so many attention we could find different companies with different applications all with one thing in common: Graphene. The Institute of Photonic Sciences (ICFO) was presenting a wearable wellness sensor in form of a transparent patch. The patch can monitor UV index and exposure, blood oxygenation, respiration rate and other health parameters. It has a low power consumption as a LED is not necessary. The patch is disposable and will have a low cost as the materials used are also of low cost. The patch is still in an early stage and it is supposed to be ready in about 1 year.

We hope for next year and the upcoming ones that the use of this super material would be by then wider and used in many applications.