The emerging field of soft robotics increasingly raises the interest of scientists. It uses materials such as silicone, cloth, balloons, and paper for enhancing the flexibility and adaptability of robots and achieving smooth and natural movements.

Read more ReWalk Robotics Says Updated U.S. VA Policy Expanded Access to its Exoskeleton

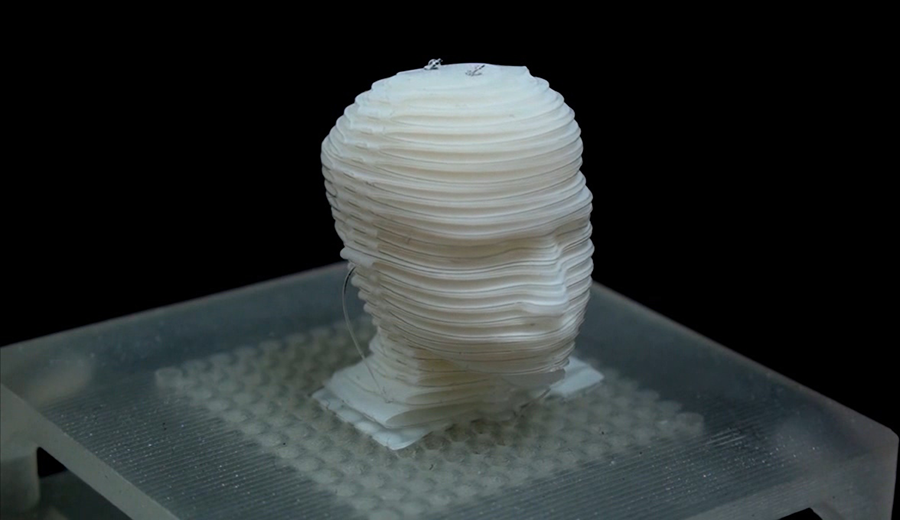

Dr. Sehyuk Yim, a researcher from the Korea Institute of Science and Technology (KIST) and his colleagues in the U.S. developed a technology that can manufacture 3D soft robots from plastic paper. The team designed geometric algorithms and realized the animation of the robots through audio-animatronics which integrate opera songs and movie monologues.

The underlying ideology of this research is to equalize future robot technologies for all people. For experienced roboticists, developing even one robot requires several weeks for designing needed mechanisms and robot structures and configuring a range of mechanical and electrical devices. Although 3D printing technology has significantly reduced the manufacturing time and cost, dozens of individual parts are still needed to be printed and assembled one-by-one. The process is very expensive.

The researchers sought to simplify the entire process with the design paradigm of soft robotics. To this end, they created a new 3D fabrication mechanism called ‘additive self-folding’ and design process for the 2D fold pattern to connect all slices of the robot. Finally, they implemented smooth, natural and lifelike motion of the soft robots using embedded tendons.

“This result is very impactful, because soft robotics now widens its application areas beyond wearable robots and/or medical robots to the art and culture technologies in which the film and entertainment industries are interested. Also, merging the soft animatronics with emerging artificial intelligence will bring forth a wide range of changes on personal robots as well as human-robot interaction field, we think,” said Dr. Yim.

This research was conducted in collaboration with robotics groups in MIT, UPENN and Univ. of York (UK). The results were published online on The International Journal of Robotics Research.