Studying heart muscle cells, or cardiomyocytes, can be very difficult because attaching rigid sensors to moving cells hinders the movement of those cells. A collaborative effort between scientists from the University of Tokyo, Tokyo Women’s Medical University and RIKEN in Japan produced a functional sample of heart cells with a soft nanomesh sensor in direct contact with the tissue. This device could aid study of other cells, organs and medicines. It also paves the way for future embedded medical devices.

Read more Scientists Develop Flexible, Conductive Mesh for Implantable and Wearable Bioelectronics

Research on the heart is fundamentally important to us all. So, when Sunghoon Lee, a researcher in Professor Takao Someya’s group at the University of Tokyo, came up with the idea for an ultrasoft electronic sensor that could monitor functioning cells, his team jumped at the chance to use this sensor to study heart cells, or cardiomyocytes, as they beat, reports the University of Tokyo Press Release.

“When researchers study cardiomyocytes in action they culture them on hard petri dishes and attach rigid sensor probes. These impede the cells’ natural tendency to move as the sample beats, so observations do not reflect reality well,” said Lee. “Our nanomesh sensor frees researchers to study cardiomyocytes and other cell cultures in a way more faithful to how they are in nature. The key is to use the sensor in conjunction with a flexible substrate, or base, for the cells to grow on.”

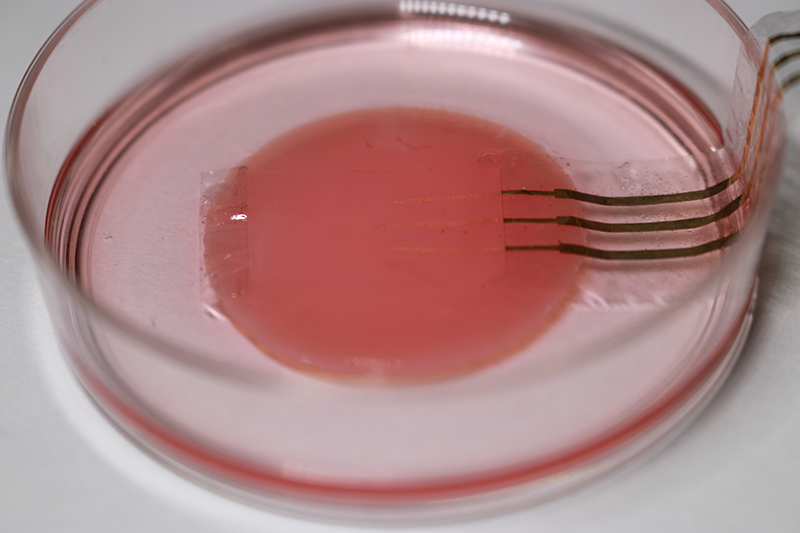

Tokyo Women’s Medical University supplied human stem cell-derived healthy culture of cardiomyocytes that had a base made of fibrin gel. Lee placed the nanomesh sensor on top of the cell culture in a complex process, which involved removing and adding liquid medium at the proper times. The cells could then be placed on the gel and proliferate throughout, and in contact with the sensor.

Read more Vaxxas Nanopatch is Novel, Cost Effective and Safe Vaccine Delivery System

To make the sensors, first a process called electro-spinning extrudes ultrafine polyurethane strands into a flat sheet, similar to how some common 3D printers work. This spiderweb like sheet is then coated in parylene, a type of plastic, to strengthen it. The parylene on certain sections of the mesh is removed by a dry etching process with a stencil. Gold is then applied to these areas to make the sensor probes and communication wires. Additional parylene isolates the probes so their signals do not interfere with one another.

“Whether it’s for drug research, heart monitors or to reduce animal testing, I can’t wait to see this device produced and used in the field. I still get a powerful feeling when I see the close-up images of those golden threads,” said Lee.