Researchers from the University of Cambridge used 3D printing, also known as additive manufacturing, techniques to create electronic fibers that are a hundred times thinner than a human hair.

Read more Face Masks Made Of Electroceutical Fabric Kills Coronavirus On Contact

The transparent conducting fibers, described Wednesday in the journal Science Advances, could be used to create a variety of biomedical devices, including moisture flow sensors and portable respiratory sensors. The researchers said their highly sensitive, low-cost sensors can be attached to a mobile phone to collect breath pattern information, sound and images at the same time.

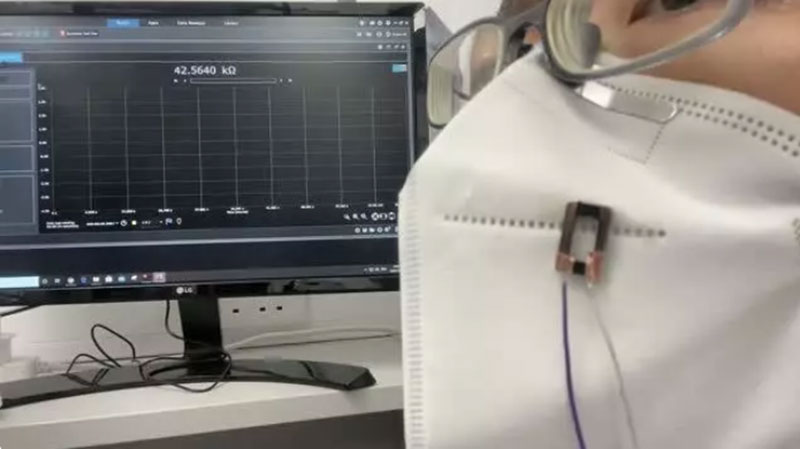

For respiratory conditions such as rapid breathing, normal breathing, simulated coughing, the amount of breath moisture leaked through face covering was tested using the fiber sensor by a Ph.D. student from Cambridge’s Department of Engineering, Andy Wang, the first author of the study.

While the fiber sensor has not been designed to detect viral particles, since scientific evidence increasingly points to the fact that viral particles such as coronavirus can be transmitted through respiratory droplets and aerosols, measuring the amount and direction of breath moisture that leaks through different types of face coverings could act an indicator in the protection ‘weak’ points, reports University of Cambridge.

The team found that most leakage from fabric or surgical masks comes from the front, especially during coughing, while most leakage from N95 masks comes from the top and sides with tight fittings. Nonetheless, both types of face masks, when worn properly, help to weaken the flow of exhaled breath.

“Sensors made from small conducting fibers are especially useful for volumetric sensing of fluid and gas in 3D, compared to conventional thin film techniques, but so far, it has been challenging to print and incorporate them into devices, and to manufacture them at scale,” said Dr Yan Yan Shery Huang from Cambridge’s Department of Engineering, who led the research.

Made from semiconducting and/or silver polymers, Huang and her colleagues 3D printed the composite fibers. This fiber printing technique creates a core-shell fiber structure, with a high-purity conducting fiber core wrapped by a thin protective polymer sheath, similar to the structure of common electrical wires, but at a scale of a few micrometers in diameter.

In addition to the respiratory sensors, the printing technique can also be used to make biocompatible fibers of a similar dimension to biological cells, which enables them to guide cell movements and ‘feel’ this dynamic process as electrical signals. Also, the fibers are so tiny that they are invisible to the naked eye, so when they are used to connect small electronic elements in 3D, it would seem that the electronics are ‘floating’ in mid-air.

Read more Graphene Facemask Kills Bacteria and Showed Potential In Deactivating Coronavirus

“Our fiber sensors are lightweight, cheap, small and easy to use, so they could potentially be turned into home-test devices to allow the general public to perform self-administered tests to get information about their environments,” said Huang.

The researchers are currently looking to develop the IFP method for a number of multi-functional sensors.