Wearable smart patches offer a wide range of possibilities in medical diagnosis and are becoming increasingly popular. These are already widely used for medical diagnosis, for example, to measure a patient’s blood sugar levels, body temperature, or heart rate. The observation of disease patterns such as skin cancer or chronic wounds is also possible.

Covestro, in collaboration with its partner accensors, has developed a concept for reusable wearable smart patches. The smart patches consist of a non-reusable element that is applied directly to the skin, and a durable element in which the electronics are integrated. The miniaturized solution contributes to resource conservation and sustainability. Covestro made this progress possible with Baymedix raw materials for adhesives and foams, as well as Platilon thermoplastic polyurethane (TPU) films. accensors has developed the sensor system and electronic modules, Covestro said in a press release.

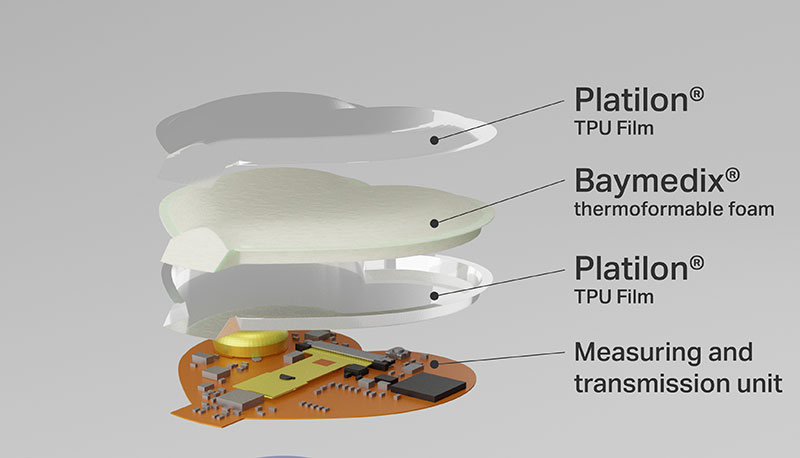

Smart patches should be as small, flexible, and unnoticeable as possible in order to offer patients a high level of comfort. The newly developed solution consists of two elements: a non-reusable element (the Disposable Patch) including sensors that is applied to the skin with an adhesive and used only once, and a reusable element, the ReUse Patch, which houses all the electronics, for example the measurement technology, power supply, data processing, radio transmission and if desired an optical camera.

High comfort, ease of use, efficient manufacturing

Thanks to Covestro materials and to integrated film sensors, the wearable patches are very lightweight, thin and flexible, and fit well to the surface of your body – you can hardly feel them. Polyurethane adhesives made from Baymedix raw materials are skin-friendly and offer low trauma when removed from the skin. Various sensors are integrated in the patch to determine vital signs, for example, pulse, pressure or temperature. Here, sensor integration is achieved by using special Platilon® films in combination with a thermoformable foam based on Baymedix. All these materials are breathable and can be efficiently processed with roll-to-roll technology.

Removing and inserting the ReUse Patch into the Disposable Patch is also very easy – thanks to an ideal combination of materials and function. accensors particularly developed a film sensor that forms the interface between the smart patch and the patient and can be equipped with varied sensors.

About accensors

Founded in 2015, accensors produces sensor systems in small, medium, and high-volume quantities. accensors operate internationally and count medical technology, pharmaceutics, and biotechnology as well as an industry among its customers. The company’s 25 employees enable the development of innovative products at the two locations Espelkamp and Munich.

Read more Covestro Unveils Smart Bracelet that Regulates Body Temperature at CES 2019

About Covestro

With 2019 sales of EUR 12.4 billion, Covestro is among the world’s largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, construction, wood processing and furniture, and electrical and electronics industries. Other sectors include sports and leisure, cosmetics, health and the chemical industry itself. Covestro has 30 production sites worldwide and employs approximately 17,200 people (calculated as full-time equivalents) at the end of 2019.