Researchers at Carnegie Mellon University (CMU) have developed liquid metal for processing with a 3D printer.

Soft, stretchable materials that are also electrically conductive are hard to come by. It’s even harder to create a circuit that withstands damage, going as far as to heal itself. For Carnegie Mellon University researchers, however, these kinds of innovations are just another day at the office. The new material they created has high conductivity and the collected energy can be used for the manufacture of wearables, for example.

Read more Carnegie Mellon Researchers Create Autonomously Self-Healing Material for Robots

In 2018, Carmel Majidi, an associate professor of mechanical engineering, and his team created a circuit that was able to electrically heal itself—that is, it could continue to function even after the main paths had been cut or damaged. Building on that development, Majidi and his team at Carnegie Mellon University’s Soft Machines Lab (SML) have made a liquid metal material capable of conducting electricity and repairing any physical damage it incurs.

“We can now suspend liquid metal in virtually any polymer or copolymer in order to tailor their material properties and enhance their performance,” Majidi said. “This has not been done before. It opens the door to future materials discovery.”

SML achieved these advancements using a liquid metal made of a gallium and indium alloy. This metal is safer than other liquid metals like mercury, authors say. These discoveries allow the technology to be expanded to other polymers, including gels. This widens the range—and effect—of their research. In fact, circuits made with liquid metals can be erased and re-drawn, making them highly adaptable, reports Madison Brewer at CMU Engineering.

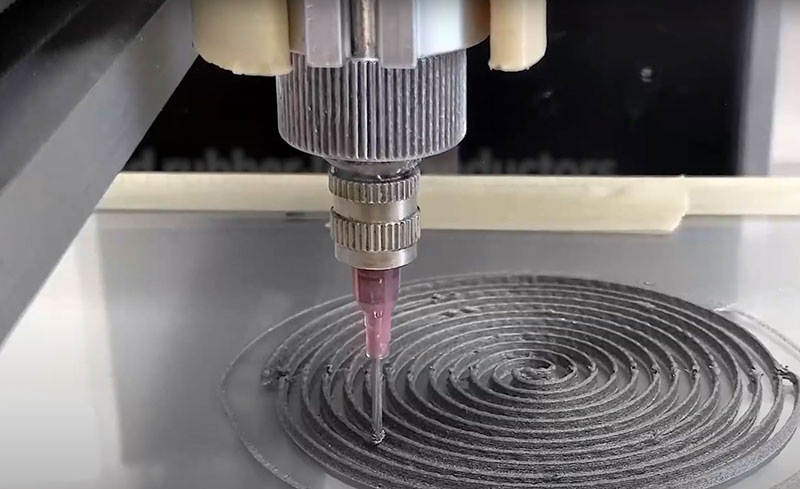

These new materials can also be 3D printed. Sarah Bergbreiter, a professor of mechanical engineering, worked with Majidi and SML to print these materials using a new manufacturing process. Creating 3D structures of these self-healing and re-writable circuits will widely expand the range of applications. One such application is energy harvesting. Energy can be generated using electricity from contact between two surfaces.

What’s more, liquid metals are highly conductive, so they can easily produce large amounts of energy. And, because the electronics are soft and stretchable, they can readily be integrated into clothing.

The electrically conducive material was worked into the fabric from which shorts were made. One subject ran in the shorts on a treadmill. After 2.2 minutes, the shorts gave him enough power to operate a thermo-hygrometer sensor with a digital screen. The team assumes that further innovations could benefit from this development. Researchers from Asia also use 3D-printed wearable sensors to generate enough electricity for wearables.

Read more Carnegie Mellon Researchers Develop Flexible Wearable Patch That Sticks to the Skin Like a Band-Aid

The researchers say potential uses of their invention could include bio-inspired robotics, human-machine interaction, wearable computing, and solar cells. These soft robotics will be highly adaptable and durable, allowing for a wide range of applications.