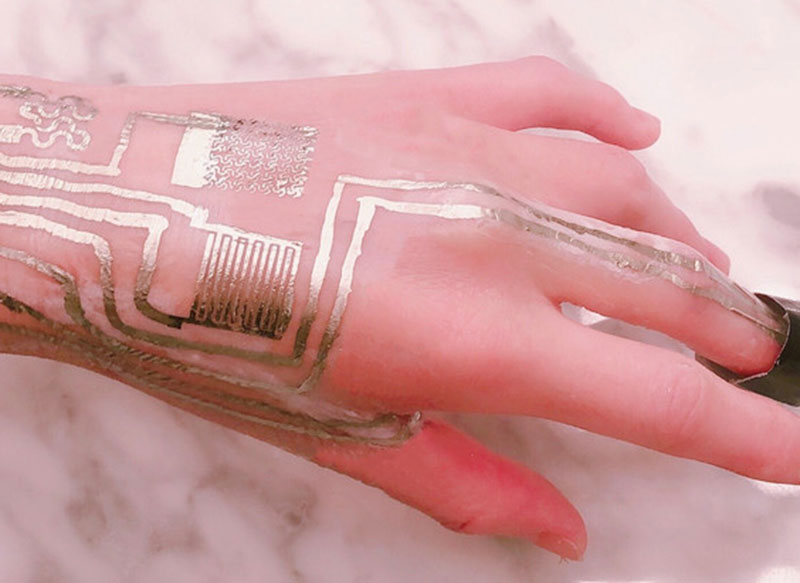

Flexible electronics have opened up some interesting possibilities. Wearable sensors, for example, are evolving rapidly. New innovations have taken wearable sensors to another dimension. Engineers can now print sensors directly on the skin, taking the form of tattoo-like films and sleeves that monitor various aspects of human health.

Read more Printed Electronics Paves the Way for Bandages, Electric Tattoos and Biosensors

Scientists at Penn State University have developed new types of sensors that they say can be safely printed directly onto the skin, where it can track things like body temperature and blood oxygen levels, before being washed off once the job is done.

“The sensors are capable of precisely and continuously capturing temperature, humidity, blood oxygen levels and heart performance signals,” the researchers say.

They also linked the on-body sensors into a network with wireless transmission capabilities to monitor the combination of signals as they progress.

The sensors can be printed directly onto the skin using a process developed by the research team that bonds a sensor’s metallic components at room temperature, rather than at the high temperatures required by other bonding or sintering processes.

High temperature sintering is normally required to bond silver nanoparticles together into flexible electronic components. At 572 degrees Fahrenheit (300 Celsius), this cannot be safely performed directly on the skin.

The research team invented a technique that bonds a sensor’s metallic components at room temperature, rather than at the high temperatures required by other bonding or sintering processes. They developed a sintering layer, consisting of a commonly used polyvinyl alcohol paste and calcium carbonate, that lets the nanoparticles bond at room temperature.

“The room temperature sintering aid layer consists of polyvinyl alcohol paste — the main ingredient in peelable face masks — and calcium carbonate, which comprises eggshells,” the researchers said.

The layer reduces printing surface roughness and allows for an ultra-thin layer of metal patterns that can bend and fold while maintaining electromechanical capabilities.

While this sintering layer allows the process to be completed at room temperature, it also makes the surface of the resulting material smoother and still flexible for on-body applications.

Using the technique, the researchers have already created blood oxygen, ECG, temperature, and humidity sensors directly on the skin. They also linked these sensors into a network which can transmit readings in real-time to a nearby monitor.