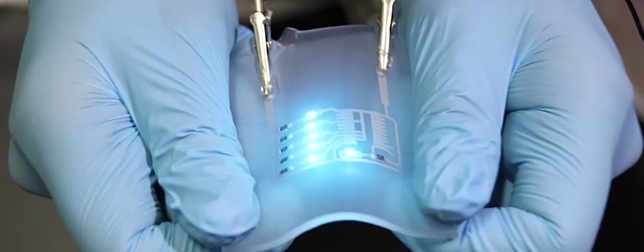

Chinese scientists have developed an innovative hybrid material – part elastic polymer, part liquid metal – that can stretch, bend, and has the potential for wearable circuits and biocompatible electronics. The material can be cast in most two-dimensional shapes and, can be totally non-toxic.

“These are the first flexible electronics that are at once highly conductive and stretchable, fully biocompatible, and able to be fabricated conveniently across size scales with micro-feature precision,” says senior author Xingyu Jiang, professor at the National Centre for Nanoscience and Technology in China.

“We believe that they will have broad applications for both wearable electronics and implantable devices.”

Read more Tiny Sensors Pave Way For New Wearable Medical Diagnostic Devices

The researchers didn’t use materials normally seen in circuits, such as copper, gold, or silver. The novel material, known as a metal-polymer conductor (MPC), features thick lumps of gallium and indium that sit within a silicon-based polymer substrate, and the metal part of the mix carries electric charges – handling the ‘circuit’ part.

The scientists further compared MPC to liquid metal islands “floating in a sea of polymer.” A liquid mantle underneath allows for the material to be fully conductive.

The team successfully tested various MPC formulations in numerous applications – from sensors in wearable keyboard gloves to electrodes embedded in cells. They note that these MPCs can be used in a number of applications.

“We cast super-elastic polymers to make MPCs for stretchable circuits. We use biocompatible and biodegradable polymers when we want MPCs for implantable devices,” says first author Lixue Tang.

“In the future, we could even build soft robots by combining electroactive polymers.”

The researchers also believe the MPC manufacturing method they developed, which involves screen printing and microfluidic patterning, can be used to produce any two-dimensional geometry. The material can also handle various thicknesses and electric attributes, which are a consequence of metal concentration in the circuits. The team believes the versatility could allow them to quickly manufacture flexible circuits for a variety of uses, from wearable tech to bioimplants.

Read more Micro Batteries and Micro Molding Solutions for Your Business

According to Jiang, biocompatibility was a principal concern, and it creates a wide range of applications beyond elementary wearable devices.

“We wanted to develop biocompatible materials that could be used to build wearable or implantable devices for diagnosing and treating disease without compromising quality of life,” Jiang said. “We believe that this is a first step toward changing the way that cardiovascular diseases and other afflictions are managed.”

The study was published in a recent issue of the interdisciplinary journal iScience.