People working in high-risk atmospheres such as mining, medicine and other forms of manufacturing are at greater risk of exposure to dangerous chemicals. What’s even worse is that some gas exposures can’t be detected.

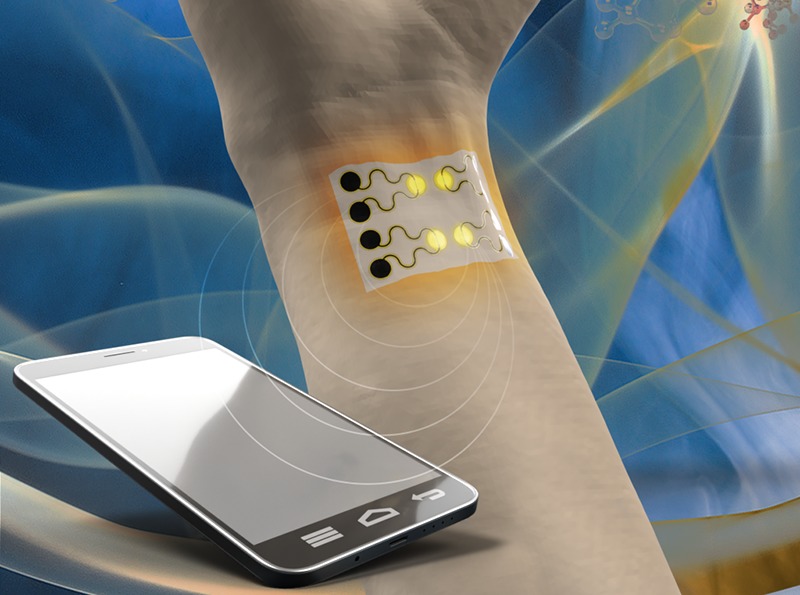

Researchers from Penn State and Northeastern University have collaborated to create a highly sensitive wearable gas sensor for environmental and human health monitoring. These devices are inexpensive, flexible and self-heating.

Read more EDF Report Finds Big Demand for Chemical Monitoring Technologies

The platform allows for a selection of chemicals to detect and devices made using this approach can be reused repeatedly. Other sensor platforms require an external heater. In addition, other wearable sensors require an expensive and time-consuming lithography process under cleanroom conditions.

“People like to use nanomaterials for sensing because their large surface to volume ratio makes them highly sensitive,” said Huanyu Cheng, assistant professor of engineering science and mechanics and materials science and engineering, Penn State. “The problem is the nanomaterial is not something we can easily hook up to with wires to receive the signal, necessitating the need for something called interdigitated electrodes, which are like the digits on your hand.”

Cheng and his team used a laser to pattern a highly porous single line of nanomaterial similar to graphene for gas, biomolecules and in the future chemical sensing. In the non-sensing portion, a series of serpentine lines are created by coating with silver. When an electrical current is applied, the gas sensing region heats up due to its significantly larger electrical resistance, eliminating the need for a heater. The serpentine lines allow the platform to stretch like springs to adjust to the flexing of the body for wearable sensors, reports Penn State Materials Research Institute.

Cheap CO2 lasers are used to create various types of these sensors. Using these sensors, the researchers were able to detect sulfur dioxide and nitrogen dioxide. The said they can make dozens of other sensors using this platform.

“Using a CO2 laser, often found in machine shops, we can easily make multiple sensors on our platform,” Cheng said. “We plan to have tens to a hundred sensors, each selective to a different molecule, like an electronic nose, to decode multiple components in a complex mixture.”

Read more Smart Equipment to Enable Hands-Free Mining in the Future

The US Defense Threat Reduction Agency (DTRA) has shown an interest in this wearable sensor to detect chemical and biological agents that could damage the nerves or lungs. A medical device company is also working with the team to scale up production for patient health monitoring, including gaseous biomarker detection from the human body and environmental detection of pollutants that can affect the lungs.