Scientists from the Lawrence Livermore National Laboratory (LLNL) have developed a new class of metamaterials that change its properties when a magnetic field is applied. The development could yield the next-generation of helmets and wearable armor.

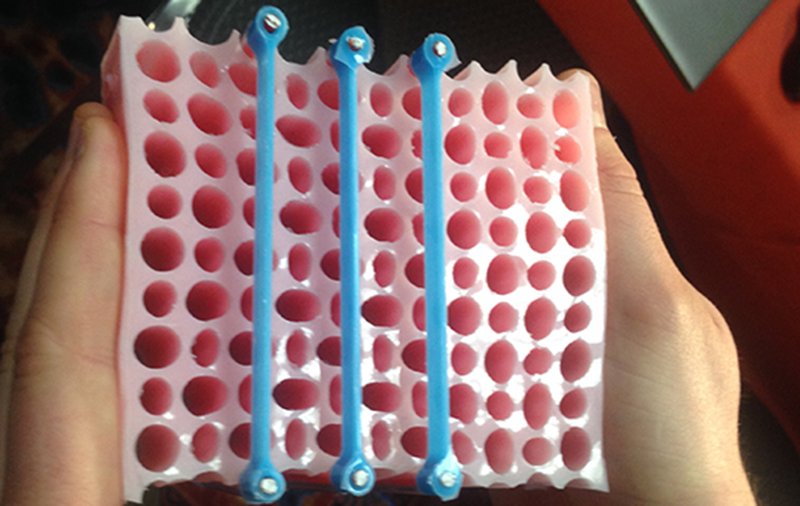

The researchers manually injected Field-Responsive Mechanical Metamaterials (FRMMs), a strong, magnetically responsive fluid into the hollow struts and beams of 3D-printed lattices. Unlike other 3D-printed materials, the overall structure of the FRMMs does not change. The fluid’s ferromagnetic particles in the core of the beams form chains in response to the magnetic field to stiffen the fluid and the lattice structure in less than a second, reports RD Mag.

After the magnetically responsive fluid enters the lattice structures, the researchers can cause the fluid to stiffen, as well as the overall 3D-printed structures by applying an external magnetic field. The change can also be easily reversed and is highly tunable by varying the strength of the applied magnetic field.

“It’s been shown that through structure, metamaterials can create mechanical properties that sometimes don’t exist in nature or can be highly designed, but once you build the structure you’re stuck with those properties,” lead author Julie (Jackson) Mancini, an LLNL engineer who has worked on the project since 2014, said in a statement. “A next evolution of these metamaterials is something that can adapt its mechanical properties in response to an external stimulus.

“Those exist, but they respond by changing shape or color and the time it takes to get a response can be on the order of minutes or hours,” she added. “With our FRMMs, the overall form doesn’t change and the response is very quick, which sets it apart from these other materials.”

Read more KIST Develops 3D Soft Robots That Look Like Living Creatures

There could be several use cases for the new technology. It could be used to make automotive seats with fluid-responsive metamaterials integrated inside with sensors that detect a crash and seats that stiffen on impact to reduce passenger motion that can cause whiplash. They can also be used to make helmets or neck braces for optical components and soft robotics.