Accumold – Clearing a Path for Innovation

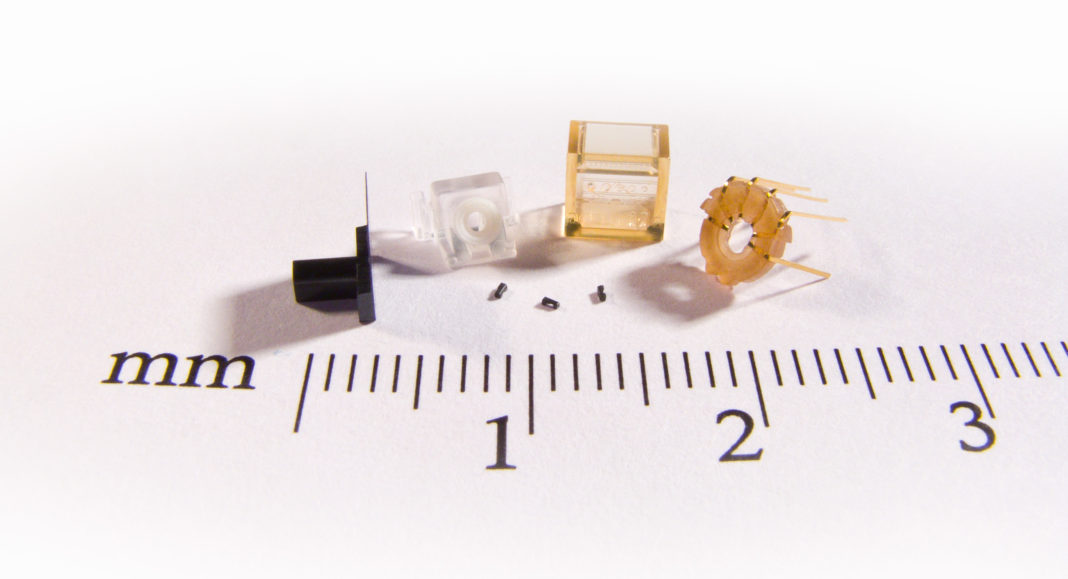

One of the key drivers Accumold has found in the wearable technology space is size. For many, successful wearable technology is almost best when it unseen or unnoticed. This maybe tech woven into fabrics or added functionality for an already packed-out device. Regardless, doing more in the same space, or more in less, seems to be top-of-mind for many design applications. This also seems to be one of the barriers to innovation.

Oftentimes there are legitimate reasons a design can stall. Energy storage or collection, material performance and other tech hardware may not be available in the format or size needed for your application. One challenge that is often discussed, and sometimes overlooked, is the formfactor. Traditional manufacturing techniques are the go-to processes but might be what is hindering your next breakthrough design. This is where a process like micro injection molding can come in handy.

Micro molding is based on injection molding principles in general but takes the size, features and tolerances to an extreme level. Many have found the hard way that micro molding is not just large molding made smaller. Considerations for the tooling, material processing, part handling and quality control require experience and knowhow not found in a textbook.

What does this mean for you? Exploring manufacturing processes like micro molding may mean that you have push beyond your current supply chain process. If your supply chain is pushing back on your design don’t take no for an answer until you are sure no is the answer. Cost considerations are almost always the reasons for scaling back or simplifying a design. While this is a reality we all must balance, ask yourself, what does not pushing ahead mean for your design, market share or company as a whole?

Clearing a path for innovation sometimes is just clearing what you know to be true and exploring what could be true. Accumold. World Leaders In High Precision Micro Molding Technology (accu-mold.com)

Learn more about Accumold and how to drive miniaturization to the next level at the VIRTUAL WT | Wearable Conference ASIA on December 10 – 12. Register here today!